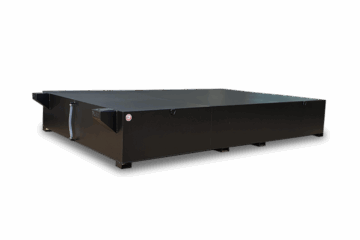

GP500 Standard

GP500 Mobile Welfare Unit

The GP500 is a spacious and well-equipped welfare unit designed to support larger on-site teams with reliable, comfortable and fully compliant facilities. Built on a double-axle design, it remains compact and towable while offering a notably larger internal layout, making it ideal for projects that require welfare provision for up to 10 people.

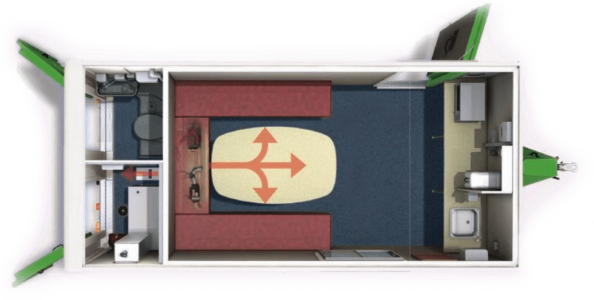

Inside, the GP500 provides a practical and comfortable environment with designated seating, washroom facilities, drying space and warm water washing, all of which are designed to meet full HSE and CDM welfare requirements. Its enhanced layout creates a spacious and safe environment for workers, supporting break and rest areas.

The GP500 accommodates up top 10, and comes equipped with a wide range of practical features designed to make life on site easier, safer, and more comfortable. Built to be spacious, towable, and highly efficient, it combines essential welfare facilities in a single unit while maintaining full HSE and CDM compliance.

Rapid Setup

Engineered for fast, efficient deployment on any site, the GP500’s twin-axle trailer design and hydraulic system allow the unit to be lowered to ground level effortlessly, enabling a single operator to position, level, and secure it in minutes. With a hydraulically damped tow coupling, multiple hitch options, and a protective steel nose cone cover, the GP500 provides smooth transport and safe installation wherever it is needed.

Fully Equipped Welfare Facilities

Built to support teams throughout the working day, the GP500 offers all essential amenities in a compact yet comfortable layout. The canteen area includes bench seating for up to 10 people, alongside a hard-wired microwave and kettle. A large stainless-steel sink with warm water, fresh wastewater containers (20L each), and paper towels, soap, and cup dispensers.

In the dedicated toilet area, a plastic recirculating toilet with a 280L tank and integrated ventilation pipe is paired with a forearm wash basin and warm water tap, delivering reliable hygiene facilities that meet site welfare regulations.

Reliable Power & Electrical Systems

The GP500 delivers dependable performance through a robust and efficient electrical setup. PIR-activated 12V LED lighting is installed throughout the unit. Power is supported by a 130Ah battery with a guard, a voltmeter, and a consumer board with RCD/MCBs. Plus 2-amp and USB charging sockets for day-to-day use.

A 6kVA diesel generator with exhaust venting, start panel, hour-run meter, and a separate fuel-level gauge, providing consistent onsite power. Combined with the Fuel Active system and a 58L fuel tank offering approximately 25 hours of runtime, the GP500 is built for long operational periods with minimal downtime.

Safe and Secure Design

Safety and security are prioritised throughout the GP500’s construction. The unit is fitted with a carbon monoxide monitor, smoke alarm, and high-level ventilation. Steel personnel doors, shuttered aluminium windows, and a steel nose cone all come equipped with the unit for added protection.

Internally, the structure is lined and insulated using GRP panels with block insulation inserts, ensuring durability and temperature control. Externally, fully hot-dipped galvanised steel chassis and profiled steel panels form a rugged outer shell built to withstand challenging site environments.

Practical Internal Layout

Offers clearly separated areas, including a canteen area, toilet, drying/generator room, each with PIR lighting, and ventilation. Coat hooks in the drying room and efficient layout planning ensure the unit operates smoothly during everyday use, supporting people with reliable workspace organisation.