Bronze award from the Defence Employer Recognition Scheme (ERS)

We are pleased to confirm that our organisation has received the bronze award…

We recently did a blog post on site safety. Looking at safety sign and fire safety in particular. This was the first post in a series. We are going to continue to look at key areas of health and safety as a reminder to some key points. We all want to stay safe at work, so it is never a bad idea to refresh our memories on site safety. Helping us to avoid any potential hazardous situations, looking after the welfare of everyone. Today we will look at manual handling, working from height and confined spaces

Manual handling constitutes anything which involves using hands or bodily force. It usually involves moving or transporting a load. Lifting, lowering, pushing, pulling, moving or carrying a load all count as manual handling. A load could be an object, equipment, person, animal or more. It is a moveable object or something that can be moved using assistance, from a roll cage for example.

Manual handling could lead to injuries such as musculoskeletal disorders if not done correctly. An injury could happen instantly from carrying a load wrong. This could be from a number of ways such as dropping the load on you. An injury could also arise from incorrectly carrying loads over a long period of time.

Before lifting a load you should follow three steps; avoid, assess and reduce.

Before even needing to carry a load you should see if there is any way of avoiding this. This could be by looking at other options for how it could be done. For example a delivery should be placed where it is intended for straight away. Rather than than being put out of the way and then moved at a later date. There may also be another way of moving a load, this could be with equipment such as a fork lift for example.

The risk of manual handling should be assessed. You should identify any risks that may come with this handling. The full workforce should be involved in the risk assessment process. Often in a risk assesment we use the accronym T.I.L.E. This stands for;

Task – The type of handling, is it lifting, lowering, pushing, pulling, etc

Individual – Each person has different capabilities when lifting, this should be considered. For example the smaller a person is the less they are likely able to handle.

Load – How much of the load is safe to handle? This all depends on the size, shape, weight and surface of the load.

Environment – factors must be considered such as: where is the object being moved? is the walk way clear?

Risk assessments are extremely important for both the employees and the employers.

After carrying out the risk assessment you should reduce and cut out any of the potential risks that arise. For example if the path way is blocked it must be cleared before the handling can take place.

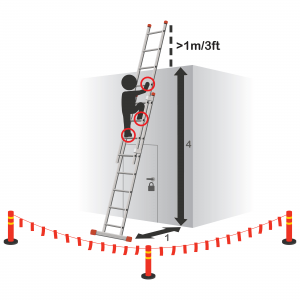

Working from height has potential to cause injuries. This is whether it is above or below ground. You can see the full HSE guidelines for them here. Before working at any height the situation must be assessed to figure out if it is safe to do so. You will also need to assess whether working at this height can be avoided completely. After assessing you will need to decide on any precautions that may need to be taken. In the risk assessment you will always need to create a rescue plan. Many of the deaths and injuries that come from working at height involves falls. Be it from a ladder, scaffolding, working platforms or through a fragile roof.

Ladders again should be avoided if there is another safer method of doing the job. They should only be used for light work. Light work is work that is only a short duration of 3o minutes or less. They need to be deemed fit for use and in good condition, there must be no visible damage. The main areas to check are the feet, the stiles, the rungs and any locking mechanisms. For step ladders you must check the platform and the steps or treads. Painted ladders should not be used as the paint could be covering damages.

When leaning ladders you must follow the 4 to 1 rule (1 unit out to every 4 units up). It should always sit at a 75 degree angle. You should never work on the top three rungs of a ladder. Holding items should be avoided when climbing. Anything needed could be passed to the user when they are up the ladder. Alternatively they could use a tool belt or a bucket. Two feet should remain on the ladder at all times when working. When climbing up you should have three points of contact at all times. Either two feet and a hand or two hands and a foot.

Be sure to check out our previous site safety reminder blog on Safety Signs and Fire Safety.